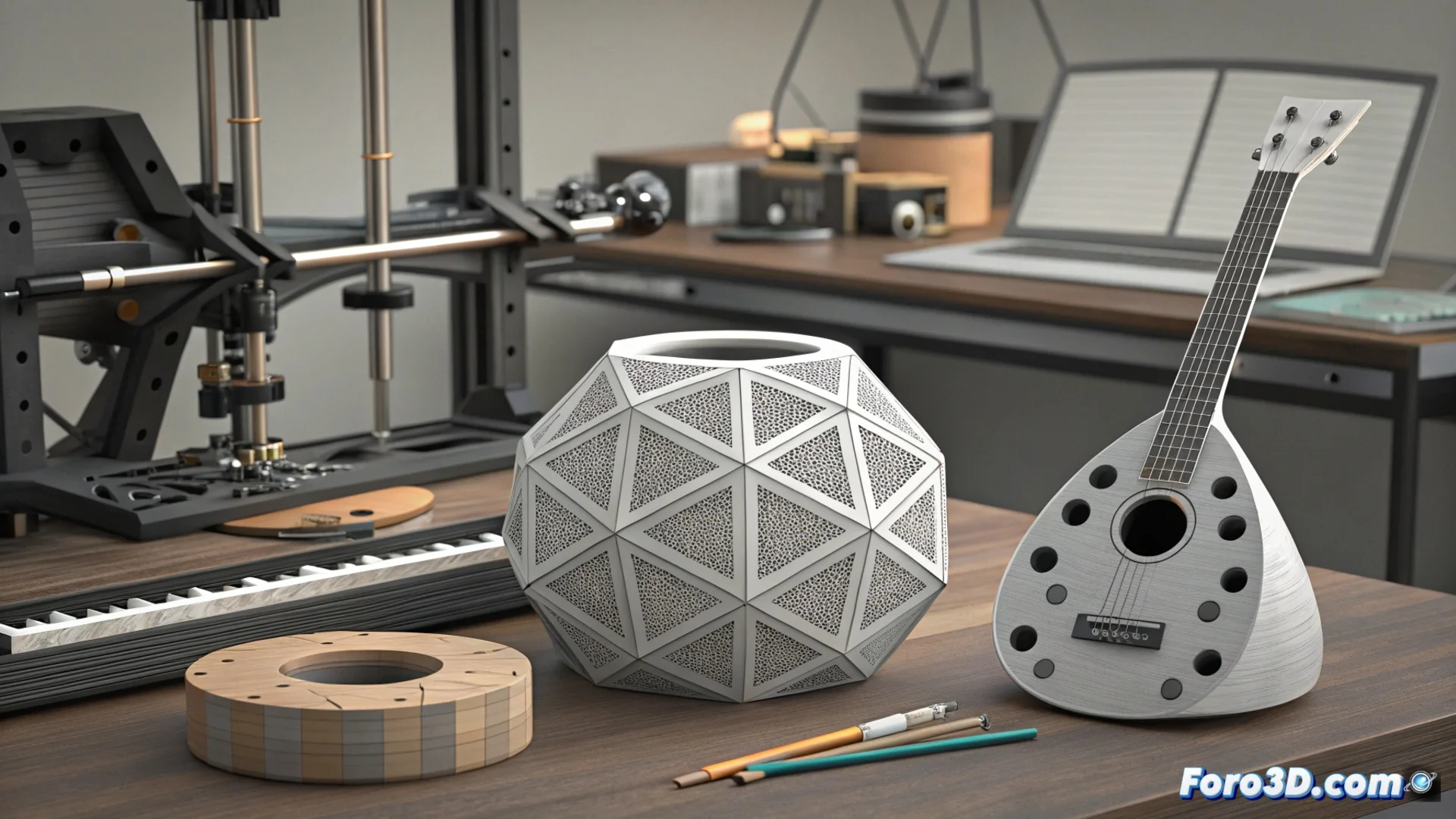

3D Printing Redefines How to Design Musical Instruments

Additive manufacturing is transforming the field of luthiery, opening the door to designing and producing instruments that explore new sonic frontiers. This technology allows materializing complex internal geometries and organic shapes that conventional carving methods cannot achieve. By using 3D printing, creators can iterate over prototypes at great speed and precisely adjust the parameters that shape the sound, from the resonance cavity to the air path. This results in a unique and distinctive timbre for each piece. 🎵

Types of Instruments You Can Manufacture

The spectrum of possibilities is wide. Percussion instruments can be produced with labyrinthine internal structures that filter and modulate sound waves. For wind instruments, like flutes or ocarinas, the location and diameter of the holes can be experimented with to tune their musical scale. In the case of string instruments, it is feasible to print the body or neck and then assemble them with standard strings and hardware. The geometric freedom inherent in the process also facilitates integrating ergonomic improvements or decorative elements directly into the piece, without complicating its manufacture.

Application Examples:- Percussion: Resonance boxes with internal channels that direct and alter the sound.

- Wind: Flutes with tone holes in unconventional positions for microtonal scales.

- String: Electric guitars with ultralight necks and organic designs impossible to mill.

3D printing not only reproduces shapes but allows inventing acoustics from scratch.

The Crucial Role of Materials and Settings

The final acoustic result depends deeply on the chosen printing material. Common filaments like PLA or ABS provide a specific sonic character, while composites with wood or metal particles can substantially modify resonance and damping. Factors such as fill density, number of perimeters, and piece orientation during printing directly influence how it vibrates and, therefore, the sound it emits. Some designs require surface post-processing or applying sealing varnishes to achieve the desired tone and projection.

Factors Affecting Sound:- Filament Type: PLA (brighter sound), ABS (more damped), composites (wood, metal).

- Printing Parameters: Fill percentage and pattern, wall thickness, bed orientation.

- Surface Finish: Sanding, application of sealers or lacquers to modify vibration.

The Challenge of Achieving the Perfect Note

One of the main challenges is calibrating the entire process so that the instrument does not sound like plastic, but possesses the qualities of a serious instrument. Achieving a printed xylophone with a clear attack and stable tuning, or a flute with a crisp air response, requires patience and multiple cycles of trial and error. The key lies in iterating over the design, meticulously adjusting the geometry and manufacturing parameters until reaching the sought-after sound. This tuning process turns the designer into a sort of digital luthier. 🎶