3D Sand Printing Casts the Dallara Stradale Chassis

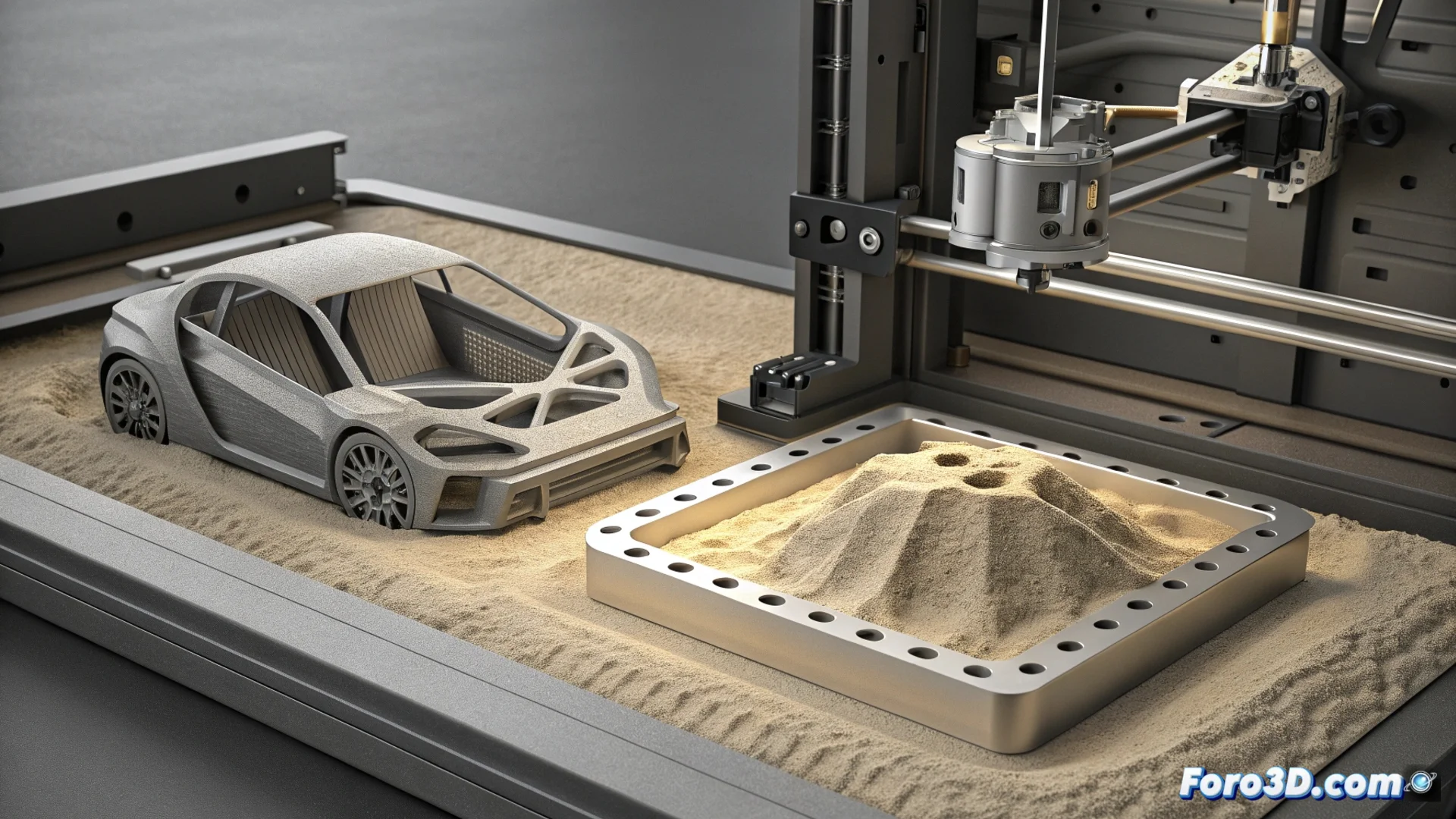

Additive manufacturing is transforming how complex prototypes are built in high-demand sectors. A paradigmatic case is the Dallara Stradale automobile, where 3D sand printing was used to manufacture the molds for the central monocoque chassis. This technological integration accelerates the design validation process and significantly reduces costs. 🚗⚙️

Casting Complex Geometries with a Click

The traditional method for making casting molds requires physical patterns, which consumes time and resources. 3D sand printing eliminates this step by building the mold layer by layer directly from a digital file. For the Stradale, this was crucial, as the aluminum chassis features intricate shapes that are difficult to machine. The technology allowed iterating on the design with unprecedented agility.

Key advantages of the process:- Produce bonded sand molds without the need for tooling or physical patterns.

- Achieve complex internal geometries that optimize the weight and rigidity of parts.

- Reduce time and cost when testing new designs in the development phase.

3D printing in this context does not aim to replace final series production, but to streamline the engineering and validation phase.

Impact on the Automobile Development Cycle

Implementing this technology allowed the Dallara team to adjust structural components with greater speed. The ability to manufacture unique parts or short runs is ideal for the prototyping stage of a high-performance vehicle. Beyond the main monocoque, it was also used for auxiliary components, demonstrating its versatility.

Benefits for engineering:- Validate designs quickly before committing investments to expensive tooling.

- Allow engineers to optimize parameters like rigidity and weight from early stages.

- Facilitate the creation of internal channels or honeycomb structures that improve performance.

A Future Molded in Digital Sand

This Dallara Stradale case illustrates how additive manufacturing is consolidating as a powerful tool in advanced engineering. It's not just about making display models, but about casting metal with digitally created molds. The technology shortens deadlines, reduces costs, and frees designers from traditional manufacturing limitations, setting a solid precedent for the development of future vehicles. 🔩🔥