When Your Battery Comes Out of the Printer Instead of the Factory

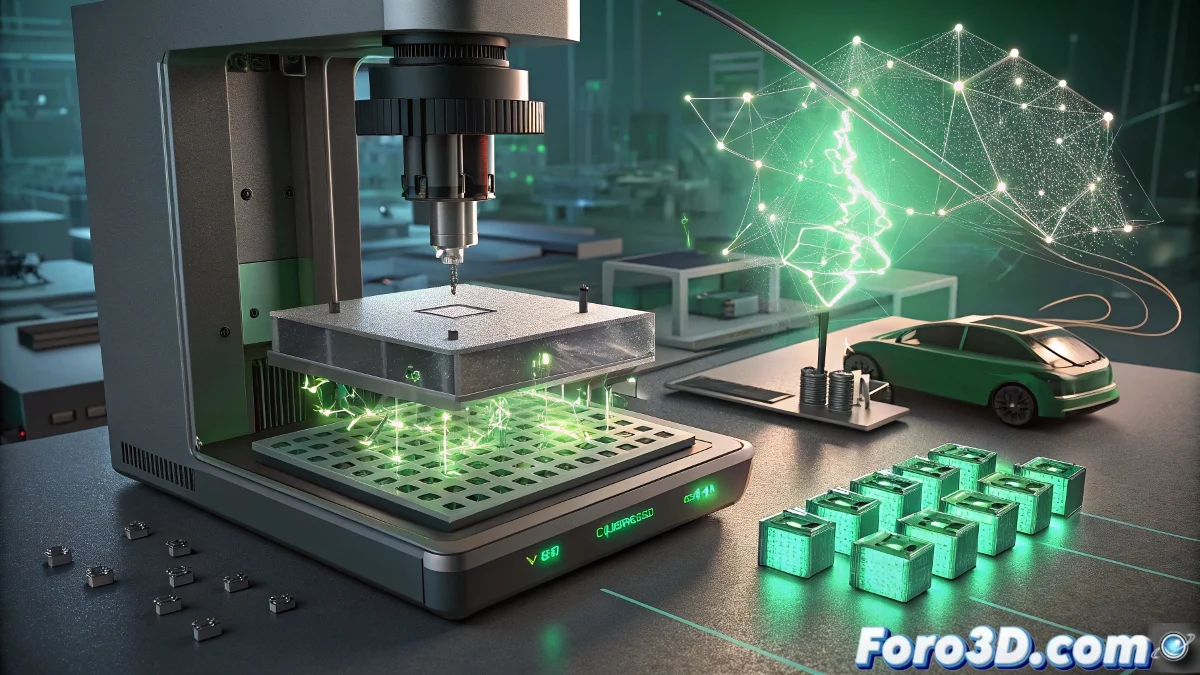

Researchers have achieved what seems straight out of a science fiction movie: 3D printing fully functional lithium-ion batteries using the drop-on-demand method. This technique, which until now was mainly used for rapid prototyping or printing simple materials, has been adapted to create one of the most complex and essential components of modern electronics. 🔋 The revolutionary part is not just that batteries can be printed, but that multilayer structures can be created with a precision impossible to achieve with traditional manufacturing methods, opening the door to completely new designs that could change how we power everything from wearables to electric vehicles.

Drop-on-Demand: The Magic of Drop-by-Drop Precision

The drop-on-demand method works like a high-precision inkjet printer, but instead of ink, it deposits active electrochemical materials. Each microscopic drop is placed exactly where it is needed, creating electrodes, separators, and current collectors with a level of control that makes traditional manufacturing seem like work with a hammer and chisel. 💧 The beauty of this approach lies in its material efficiency: there is almost no waste, and internal structures can be created that optimize surface area (and thus battery capacity) while minimizing occupied volume. It's the energetic equivalent of folding origami at the nanoscale.

Key advantages of this method:- Micrometric precision in material placement

- Minimal waste of costly or toxic materials

- Ability to create complex internal geometries

- Direct integration with other components during printing

Applications That Sound Futuristic But Are Closer Than We Think

The implications of this technology are enormous. Imagine a smartwatch whose battery is printed directly into the case, making use of every available cubic millimeter. Or a drone with batteries integrated into the structure of its wings, eliminating the dead weight of separate compartments. 🚀 In the medical field, we could see implants with customized batteries that perfectly adapt to the patient's anatomy. And in electric vehicles, batteries could be printed in shapes that structurally integrate into the chassis, increasing safety and energy efficiency simultaneously.

The Challenges: Why You Won't Print Your Power Bank Tomorrow

Despite the understandable enthusiasm, this technology still faces significant obstacles before reaching the mass market. The long-term durability of the interfaces between printed layers needs validation, especially considering the expansion and contraction that battery materials undergo during charge-discharge cycles. ⚠️ Thermal stability is another critical concern, as lithium batteries can be temperamental when heated. And then there's the challenge of scaling production: printing a battery for a small device in the lab is one thing, but producing thousands for the consumer market is completely different.

Active research areas:- Development of printing materials with better cyclic stability

- Optimization of printing parameters for different geometries

- Integration with packaging and thermal management systems

- Validation of safety under extreme conditions

The Future: Battery Printers Next to Plastic Ones?

It's tempting to imagine a future where electronics stores have specialized 3D printers that manufacture custom batteries while you wait, or where device manufacturers print their own power sources on demand instead of relying on global supply chains. 🏭 Mass customization would be the holy grail: batteries designed specifically for your usage pattern, with the exact shape your device needs, and chemistry optimized for your specific requirements. But getting there will require not only technical advances, but also changes in how we think about battery ownership, recycling, and safety.

Environmental Impact: The Double-Edged Sword

This technology presents interesting ecological implications. On one hand, localized manufacturing would reduce the carbon footprint of transportation, and the precision of drop-on-demand would minimize material waste. ♻️ On the other hand, it poses challenges for recycling, as highly customized and integrated batteries could be harder to disassemble and process. The final balance will depend on how we develop both the printing technology and circular economy systems to manage the end-of-life of these customized batteries.

The real revolution won't be printing batteries faster, but printing smarter batteries

Conclusion: Charging Toward a Customized Future

3D printing of lithium-ion batteries using drop-on-demand represents one of those advances that could reconfigure entire industries. It's not just a more efficient manufacturing method, but a fundamental shift in how we conceive and design energy storage. ⚡ For 3D printing enthusiasts, it's exciting to see how this technology continues to expand its boundaries, demonstrating that its potential is far from exhausted. And for the rest of the world, it's a reminder that sometimes the most transformative innovations don't come from creating something completely new, but from finding new ways to do something we already take for granted. After all, what could be more fundamental in our modern world than the way we store the energy that makes it work? 😄