The Expansion of 3D Printing in Various Industries

3D printing continues its advancement and is applied in a variety of sectors, from vehicle design to the creation of medical devices. Companies from different areas are leveraging this technology to optimize processes, reduce costs, and offer more personalized products, driving its global adoption.

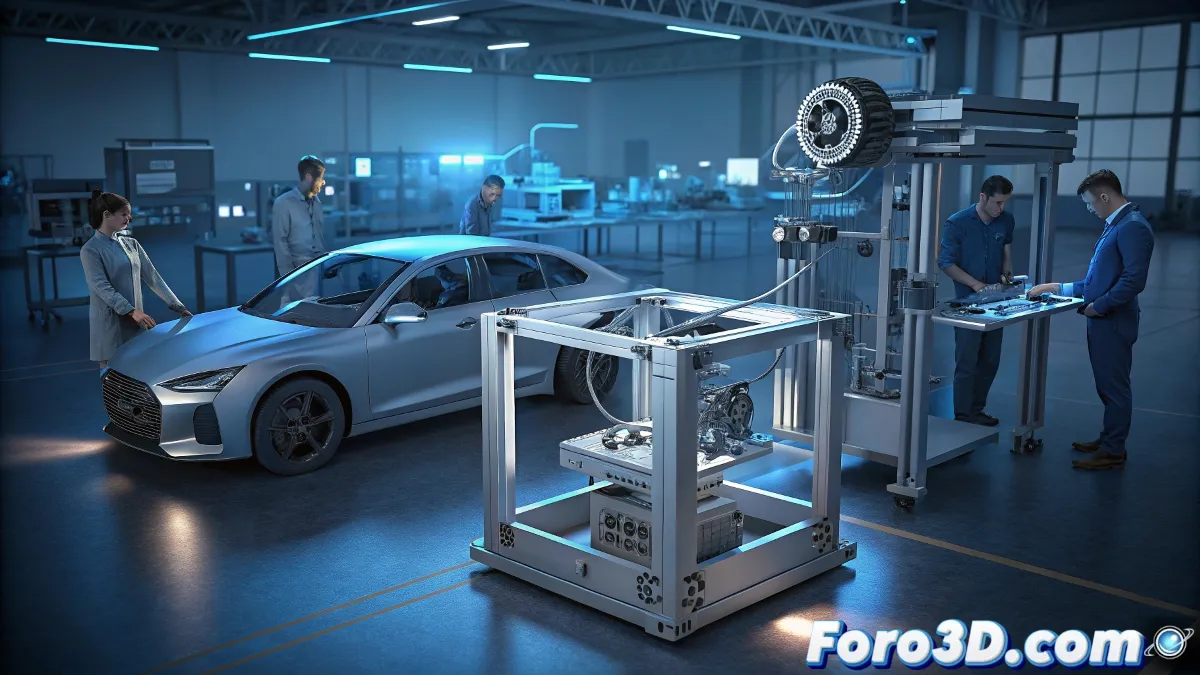

Applications of Luxury Materials in Automotive

One of the areas where 3D printing has had a significant impact is the automotive industry. Recently, a high-end car manufacturer has begun incorporating interior components printed with 18-karat recycled gold. This process combines traditional techniques with the precision of additive manufacturing, allowing key design details to be customized without sacrificing the vehicle's aesthetics or functionality.

3D Printing in the Educational Field

The educational sector has witnessed an increase in the availability of programs that incorporate 3D printing into their curricula. Recent initiatives have enabled students aged 14 to 22 to participate in innovation projects where, with the help of industry mentors, they develop prototypes to solve real-world challenges. These types of programs not only reinforce their academic knowledge but also provide them with valuable practical skills in the product creation process.

Creation of Strategic Alliances in the 3D Printing Market

The growing demand for 3D printers and specialized materials has led to new collaborations between manufacturers and distributors. Recently, agreements have been signed to expand the availability of 3D printing technologies in sectors such as aerospace, dental, and consumer products. These alliances are facilitating the integration of additive manufacturing into large-scale production, making it easier to transition from prototyping to serial manufacturing.

Advances in 3D Printing Materials

Developments in materials used for 3D printing are crucial for its evolution. Fire-resistant resins, specially designed for creating microscale parts, have been introduced that can withstand high temperatures without compromising safety. Additionally, recycled polymers that combine performance and sustainability have also been launched to the market, allowing companies to meet industry demands without sacrificing structural quality.

Improvements in Tool Manufacturing with 3D Printing

Tool manufacturing has also benefited from 3D printing, especially with recent software updates that optimize process efficiency. These improvements have enabled production time reductions of up to 20%, eliminating the need for manual adjustments on complex parts. These innovations aim to make automation in manufacturing more accessible, contributing to increased productivity and reduced operational costs.

Transformation of the Medical Sector with 3D Printing

3D printing is leaving a significant mark on the medical industry, particularly in the creation of innovative orthopedic devices. Implants with biomimetic structures improve bone integration and load distribution, optimizing surgical treatments. Likewise, the technology sector has benefited from the ability of high-precision printers to produce parts with advanced materials, opening new possibilities in areas such as robotics and biomedical engineering.

Looking to the Future of 3D Printing

3D printing continues to evolve and transform the way products are designed and manufactured in a variety of industries. With the incorporation of more sophisticated materials, advances in software, and new marketing strategies, this technology is establishing itself as a key pillar in industrial innovation. Its ability to offer sustainability, customization, and efficiency ensures that it will continue to play a fundamental role in the future of manufacturing.