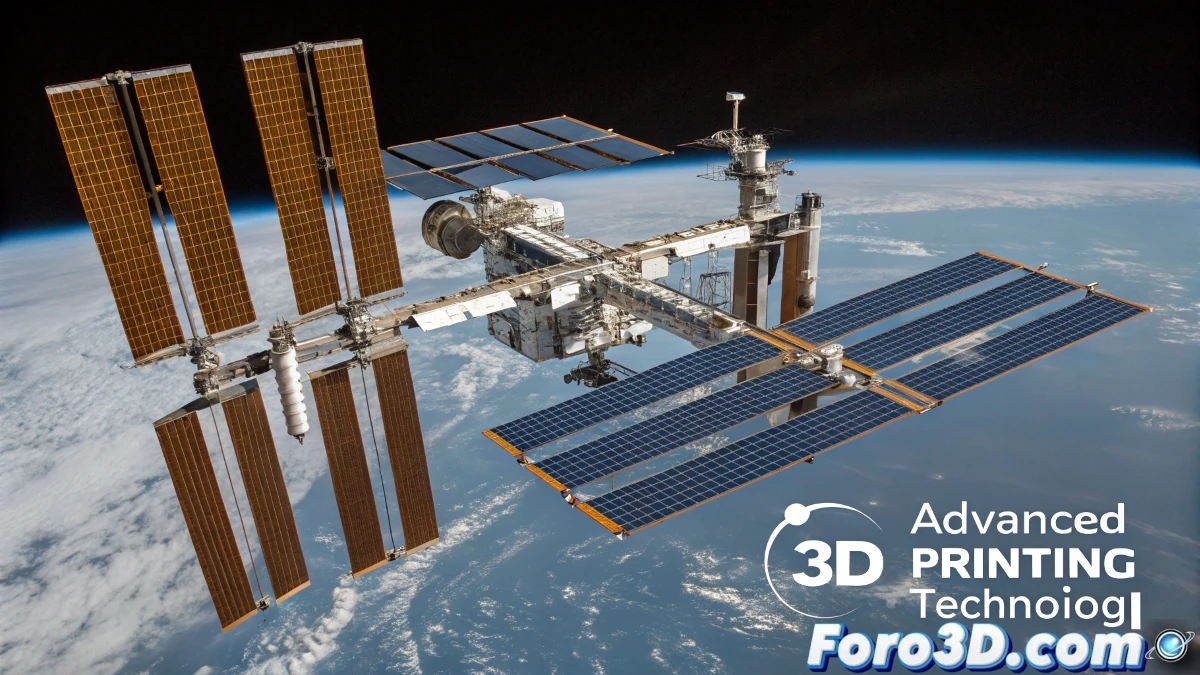

In an advancement that redefines the boundaries of manufacturing in space, a 3D printed metal component has successfully returned to Earth for testing. This achievement, carried out aboard the International Space Station (ISS), marks the first time a metal part created in orbit has returned to the planet. This project is part of a series of innovations that began in January 2024, when the European Space Agency (ESA) installed a metal additive manufacturing system in the Columbus laboratory module.

Key Tests to Understand Manufacturing in Microgravity

The printed component will be analyzed in the Materials and Electrical Components Laboratory at the Space Research and Technology Centre (ESTEC). There, it will be compared with similar samples printed on Earth to study how microgravity affects the printing process and material quality. Additionally, a second sample will be sent to the Technical University of Denmark (DTU), where research on space manufacturing will continue.

"This is a crucial step in understanding how microgravity influences the manufacturing of metal parts, knowledge essential for future space missions."

Test Objectives

- Quality comparison: Analyze differences between parts printed in space and on Earth.

- Microgravity impact: Study how it affects the printing process.

- Material optimization: Improve the quality and durability of parts manufactured in orbit.

The Metal3D Project: A Long History of Innovation

Although polymer 3D printers have been present on the ISS since 2014, the arrival of metal 3D printing technology in January 2024 represented a significant leap. This project, known as Metal3D, began in 2016 when the ESA awarded a contract to Airbus Defence & Space to develop a metal 3D printing system capable of operating in microgravity. This advancement is part of an ongoing effort to improve self-sufficiency in space, allowing astronauts to manufacture essential parts and repair equipment without relying on costly resupply missions.

Benefits of the Metal3D Project

- Self-sufficiency: On-demand manufacturing of parts and tools.

- Cost reduction: Less dependence on resupply missions.

- Continuous innovation: Development of technologies for future missions.

Towards Self-Sufficiency in Space

The ESA's long-term goal is for astronauts to be able to produce what they need without waiting for supplies from Earth. This type of advancement is crucial to ensure self-sufficiency in future space missions, especially in long-duration exploration projects, such as the colonization of the Moon or Mars. 3D printing in space not only promises to revolutionize the manufacturing of tools and spare parts but can also play a key role in creating complex structures that could not be transported from Earth due to weight limitations.

Implications for the Future

- Space exploration: Facilitate long-duration missions.

- Colonization: Manufacturing of structures on the Moon and Mars.

- Efficiency: Reduction of costs and times in space missions.

A Future of Infinite Possibilities

3D printing in space is not only a tool for manufacturing parts but also a gateway to new possibilities in space exploration and colonization. With each advancement, such as the successful return of this metal component, humanity takes one step closer to a future where space is not just a destination, but a place to live and work.

"3D printing in space is more than a technology; it is a revolution that will allow us to explore and inhabit the cosmos like never before."

The Path Ahead

- Continuous innovation: Development of new technologies for space.

- Global collaboration: Joint work between space agencies and companies.

- Sustainable exploration: Use of local resources for manufacturing in space.

With each achievement, such as this orbitally printed metal component, the ESA and its collaborators are laying the foundations for a future where manufacturing in space is an everyday reality, driving the exploration and colonization of the universe.