Taming Glass with Heat and Digital Precision

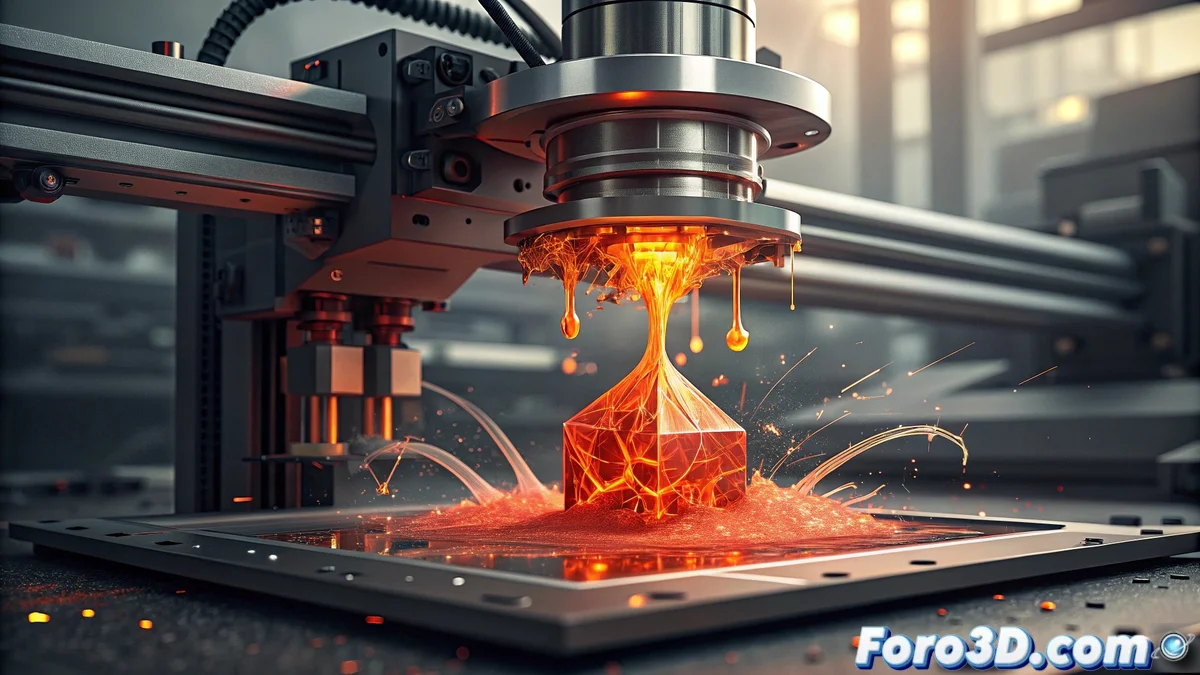

Molten glass extrusion printing represents one of the most visually spectacular methods within additive manufacturing. This technique adapts the basic principle of traditional FDM printing but elevates the temperature to extreme levels, transforming solid glass into a malleable material that can be deposited layer by layer. A process that combines traditional craftsmanship with the precision of modern digital manufacturing.

The Delicate Ballet of High Temperatures

The success of this technique depends entirely on precise control of thermal conditions at every stage of the process. From the initial melting of the glass to the final controlled cooling, every degree Celsius makes the difference between a successful piece and a pile of fragments. Post-print annealing is particularly crucial for releasing internal stresses and preventing spontaneous fracture of the finished pieces.

Critical Stages of the Process

- Material melting at temperatures above 1000°C

- Controlled deposition through specialized nozzles

- Gradual cooling in thermal chambers

- Annealing to eliminate internal stresses

Advantages that Justify the Technical Challenge

This methodology allows creating pieces of considerable dimensions that would be impossible with other glass printing techniques. The resulting aesthetics, with its visible layers and fluid shapes, has a unique character that recalls traditional blown glass but with digitally controlled geometry. Moldless customization opens unlimited creative possibilities for designers and artists.

Current Limitations of the Technique

- Surface finish requiring post-processing

- Limited precision for tiny details

- High energy consumption due to temperatures

- Risk of fracture during cooling

A technology that transforms one of humanity's oldest materials into a medium for contemporary digital expression.

For architects and designers, this technique means being able to incorporate glass into projects with organic geometries or customized patterns that challenge the limits of conventional manufacturing. The possibility of creating unique elements for specific projects without incurring prohibitive mold costs represents a significant advancement 🏺.

And all this while demonstrating that, although glass remains as temperamental as ever, at least now we can blame the software when a print goes wrong... though the problem is probably still that someone opened the window during the critical cooling phase 😅.