The 3D Revolution in the Operating Room: Millimetric Precision for the Smallest Patients

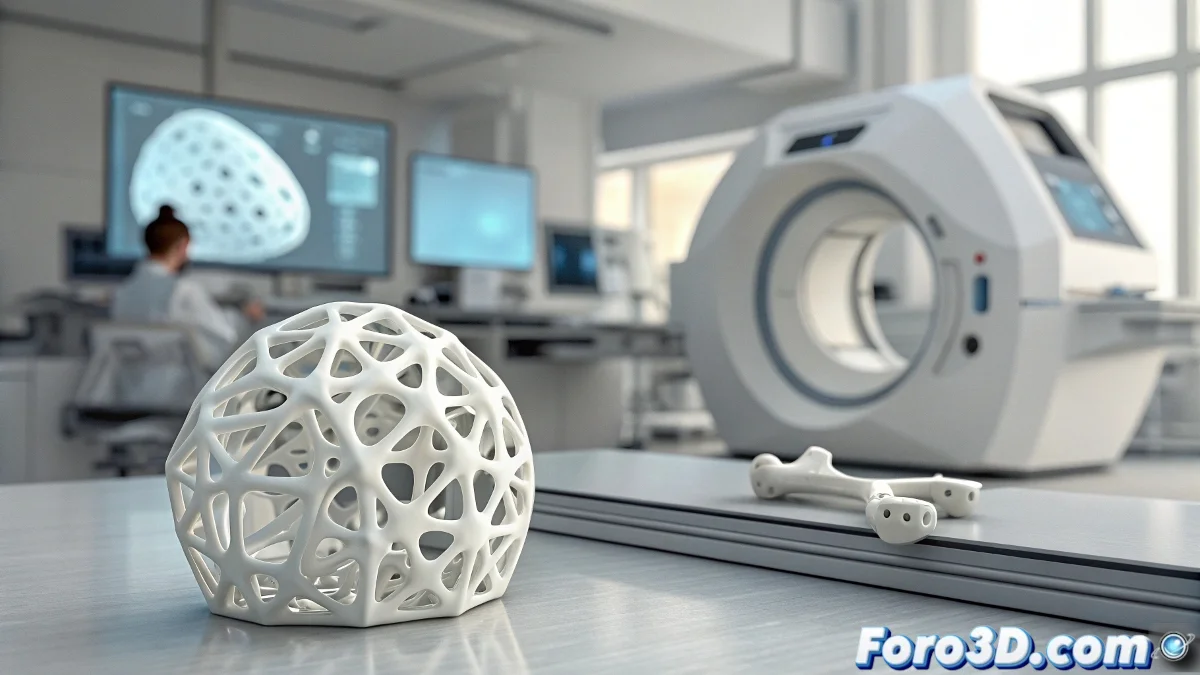

3D printers have crossed the laboratory threshold to install directly in surgical environments, radically transforming the way we approach complex interventions. These specialized machines manufacture on-demand sanitary parts and create fully customized bone spacers for pediatric reconstructions, offering anatomically perfect solutions that were impossible with traditional techniques. This technology not only optimizes procedures —in many cases, it makes possible what was previously unthinkable in pediatric surgery. 🏥✨

Intraoperative Manufacturing: When the Operating Room Becomes a Precision Workshop

Current medical 3D printers are equipment specifically designed for hospital environments, complying with the strictest sterility and safety protocols. Operating in rooms adjacent to the main operating room, they can produce instruments and components during the surgery itself, adapting to unexpected intraoperative findings and providing immediate solutions.

Pediatric Bone Spacers: Customization as the Standard

In the pediatric field, where every millimeter counts and growth is a critical factor, 3D-printed spacers represent an unprecedented qualitative advance.

Design Based on Precise Imaging

Each spacer is digitally designed from the patient's CT scans or MRIs, creating 3D models that accurately replicate individual anatomy. This process allows preserving critical structures like growth plates and adapting to unique bone curvatures.

Materials that Understand Growth

The materials used include resorbable biopolymers that gradually give way to natural bone, and porous scaffolds that facilitate vascularization and cellular integration. Some even incorporate channels for the controlled release of bone growth factors.

Specific Applications in Pediatrics:- Cranial reconstruction in complex craniosynostosis

- Intervertebral spacers for severe scoliosis

- Customized implants after bone tumor resection

- Mandibular reconstructions in congenital malformations

Sanitary Parts: On-Demand Manufacturing in the Hospital

Beyond implants, 3D printers produce customized surgical instruments and components that optimize every procedure.

Surgical Guides and Templates

Millimetric cutting guides are manufactured that fit perfectly to the patient's anatomy, ensuring precision in osteotomies and implant placement. These tools significantly reduce the margin of human error and shorten operating times.

Customized Auxiliary Devices

From endoscope holders to tissue protectors designed for specific procedures, on-demand manufacturing eliminates the need to maintain extensive inventories of specialized instruments.

In pediatric surgery, where anatomy is unique and the margin for error is minimal, 3D printing is not a luxury —it is a necessity that redefines what is possible to achieve.

Integrated Workflow in the Hospital Environment

The implementation of this technology follows a multidisciplinary protocol involving all actors in the surgical process.

Preoperative Phase: Collaborative Planning

Surgeons, radiologists, and biomedical engineers work together on the virtual design of the implant, performing simulations that anticipate the final outcome and optimize the surgical approach.

Intraoperative Phase: Real-Time Adaptation

The ability to modify designs during surgery based on real findings provides invaluable flexibility, particularly when intraoperative anatomy differs from what was expected.

Documented Benefits:- Reduction of up to 60% in anesthesia times in children

- Decrease in intraoperative complications

- Better anatomical integration of implants

- Faster and less painful recovery

Advanced Medical Materials for 3D Printing

The evolution of biocompatible materials has dramatically expanded surgical applications.

Latest-Generation Medical Polymers

Materials like medical PEEK (Polyether Ether Ketone) offer mechanical properties similar to bone and excellent biocompatibility. Hydroxyapatite composites promote direct osteointegration.

Metals for Medical 3D Printing

Porous medical titanium allows creating lattice structures that mimic natural bone density, facilitating biological integration while providing immediate structural support.

The Immediate Future of 3D Printing in the Operating Room

Upcoming frontiers include bio-printing of tissues with patient cells, implants with integrated sensors for postoperative monitoring, and augmented reality systems that overlay 3D models directly onto the surgical field.

Democratization of Surgical Excellence

As the technology becomes more accessible, regional hospitals can offer levels of customization previously reserved for reference centers, reducing family travel and improving equity in access to advanced care.

The integration of 3D printers in operating rooms represents a paradigm shift in personalized medicine, transforming surgery from a standardized approach to one where every solution fits perfectly to the individual patient —especially crucial for children, whose growing bodies deserve the most precise and carefully designed solutions. 👶💝