When Nanotechnology Meets Elastic 3D Printing

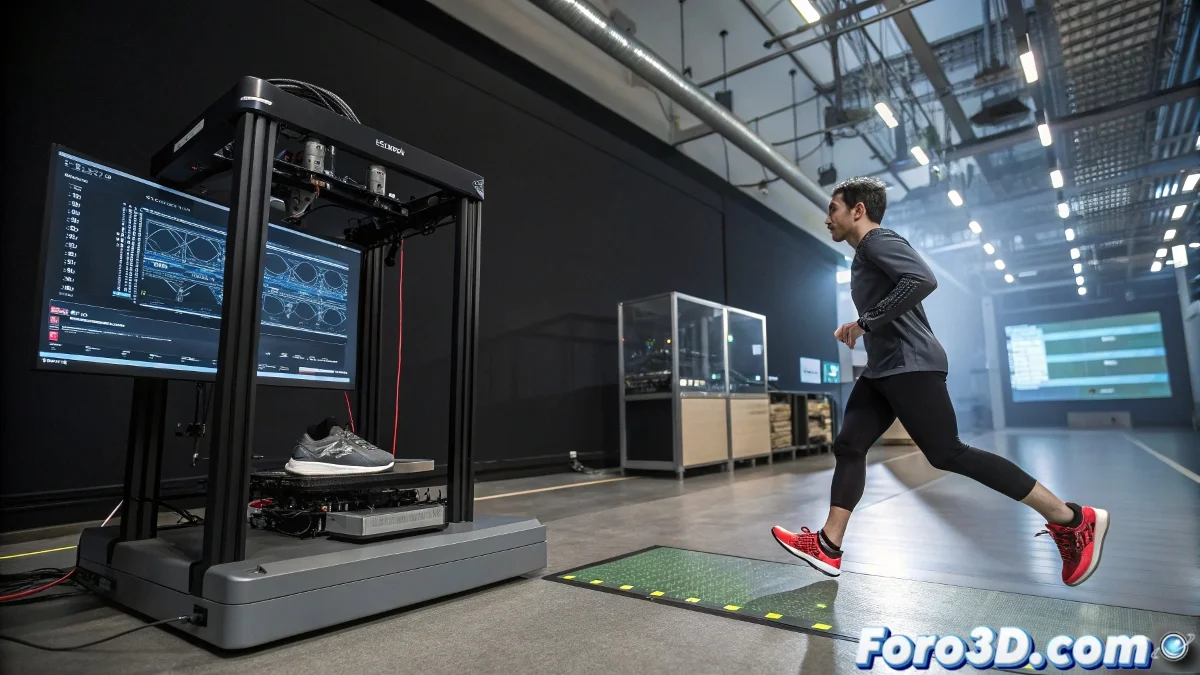

The SeoulTech team has achieved a significant breakthrough at the intersection of additive manufacturing and flexible electronics by developing carbon nanotube nanocomposite sensors that can stretch and bend without losing functionality. This innovation represents a qualitative leap in the production of wearable devices, particularly for applications where flexibility and durability are crucial, such as in smart insoles that must withstand constant cycles of compression and flexion during human gait. The ability to 3D print these sensors directly in their final form eliminates complex manufacturing processes and allows for custom personalization for different foot types and walking patterns.

What makes this development particularly revolutionary is how it solves the fundamental challenge of wearable electronics: the incompatibility between rigid components and flexible biological surfaces. The CNT nanocomposites maintain electrical conductivity even when stretched significantly, enabling consistent pressure and motion measurements regardless of material deformation during physical activity. This property is essential for podiatric applications where precise measurements can mean the difference between early detection of biomechanical issues or overlooking conditions that could lead to chronic injuries.

Innovative Technical Features

- Carbon nanotubes integrated into an elastic polymeric matrix

- Stretching capacity up to 200% without losing conductivity

- Direct 3D printing of sensor circuits in complex geometries

- Compatibility with different types of footwear and activities

The Science Behind Conductive Flexibility

The secret to the success of these sensors lies in the nanoscopic architecture of the composite material. Carbon nanotubes, known for their excellent electrical conductivity and mechanical strength, are dispersed in an elastic polymeric matrix in such a way that they maintain contact with each other even when the material stretches. This percolating network of nanotubes creates multiple redundant conductive pathways, ensuring that if some connections break during deformation, others maintain overall conductivity. The result is a material that behaves electrically like a metallic conductor but mechanically like a soft elastomer.

These nanocomposite sensors demonstrate that the true revolution in wearables is not in making devices smaller, but in making them more compatible with the human body

From a manufacturing perspective, the 3D printing of these materials represents a paradigm shift in how we produce flexible electronics. Traditional methods for creating stretchable sensors involve multi-stage processes that include lithography, deposition, and transfer - all requiring specialized facilities and generating significant waste material. SeoulTech's approach allows for the creation of complex sensors in a single step, with geometries optimized for specific sensitivity and pressure distribution that would be impossible or prohibitively expensive with conventional techniques.

Applications in Health and Sports

- Early detection of biomechanical and podiatric problems

- Monitoring of athletic technique and injury prevention

- Personalized rehabilitation based on objective data

- Optimization of sports and orthopedic footwear

The SeoulTech team's development has implications beyond smart insoles. The underlying technology could be applied to a wide range of biomedical devices, from cardiac monitoring patches to sensors integrated into sports clothing. For the 3D printing industry, it represents another demonstration of how additive manufacturing is transcending rapid prototyping to become a tool for producing advanced functional devices. And for end users, it brings closer the promise of personalized and preventive healthcare through discreet, comfortable, and accessible technology. 👣

And so, between carbon nanotubes and elastic polymers, the SeoulTech team demonstrates that sometimes the most significant advances in wearable technology don't come from making smaller circuits, but from making them more like us: flexible, adaptable, and remarkably resilient - though probably with better posture than most modern humans. 🏃♂️