What are conductive nanocomposites?

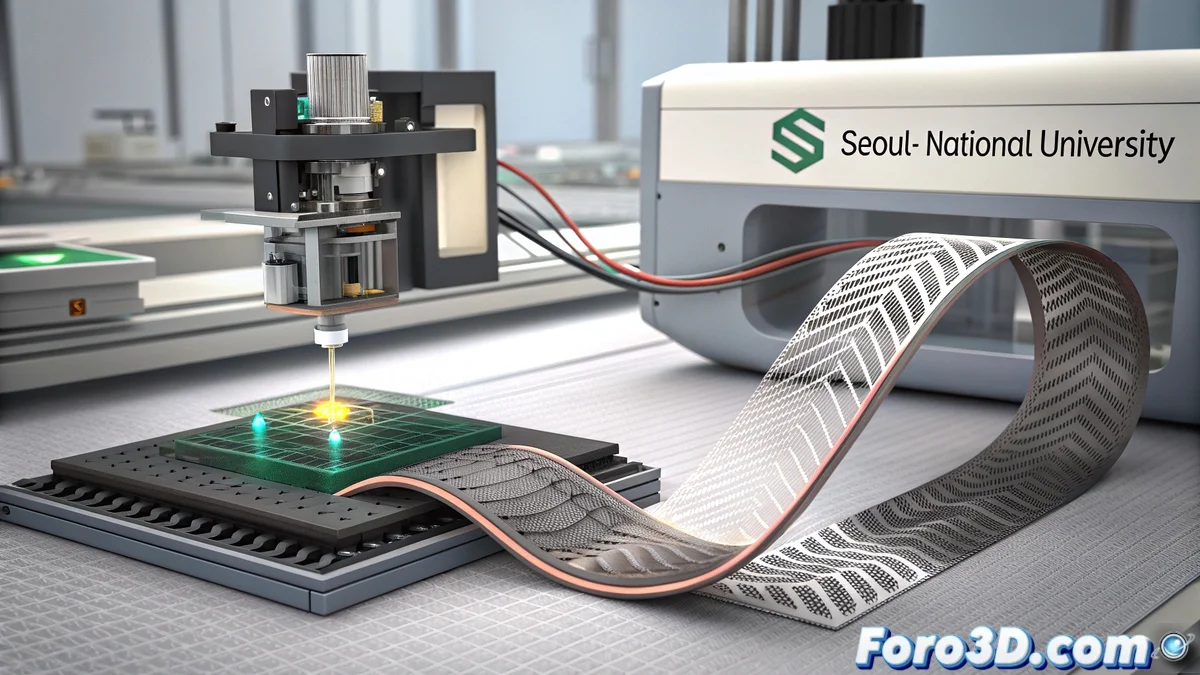

The boundary between electronics and biology is blurring more and more thanks to recent advances in smart materials. 🔬 Researchers from Seoul National University have developed conductive nanocomposites through 3D printing that combine the flexibility of polymers with the conductivity of metallic and carbon nanoparticles. These hybrid materials represent a perfect balance between mechanical elasticity and efficient electrical transmission, enabling the fabrication of sensors that adapt perfectly to the unique topography of the human body. The ability to print these structures in 3D opens unprecedented possibilities for mass customization in the field of digital health and next-generation biomedical devices.

Applications in wearable sensors

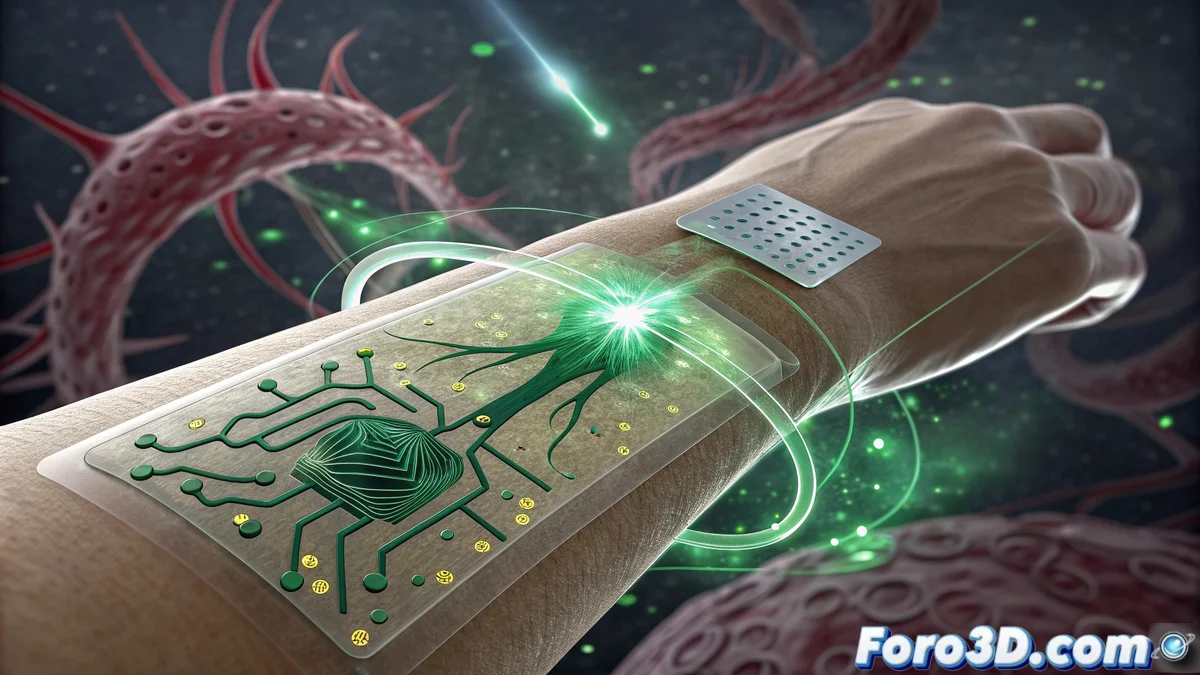

The practical implications of this technology extend to multiple domains of biomedical monitoring and human-computer interaction. Sensors made with these nanocomposites can record vital parameters such as heart rate, body temperature, and sweat composition with extraordinary precision. Their advanced sensitivity even allows detection of micro muscle contractions and subtle facial expressions that escape conscious perception, finding immediate applications in physical rehabilitation, sports performance optimization, and development of smart prostheses that respond to nearly imperceptible neuromuscular signals.

These materials combine mechanical flexibility with high electrical conductivity

Benefits over current technologies

The 3D printing approach for nanocomposites significantly overcomes the limitations of traditional manufacturing methods for flexible electronics. Production cost reduction is substantial by eliminating multiple manufacturing stages and enabling direct fabrication from digital models. Development times are dramatically shortened, facilitating rapid iterations and customizations specific to particular use cases. Perhaps most importantly is the qualitative leap in user comfort, as the end user experiences an almost imperceptible integration between device and body without sacrificing monitoring capabilities.

The paradox of insignificant nanoparticles

One of the most fascinating aspects of this technology lies in its apparent fundamental contradiction. Conductive nanoparticles, considered individually, represent nearly disposable material with no practical utility. However, when strategically dispersed within a polymeric matrix through 3D printing, these microscopic particles create conduction networks that transform a basically insulating material into an efficient conductor. This functional metamorphosis demonstrates how structural organization can turn seemingly insignificant elements into critical components of advanced technological systems.

Amplifying human perception

Nanocomposite sensors do not limit themselves to imitating human sensory capabilities, but amplify them to previously unattainable levels. Where our skin perceives pressure or temperature qualitatively, these devices provide precise quantitative measurements of stimuli too subtle for our nervous system. This ability to quantify the imperceptible creates a technological extension of our biological senses, enabling not only monitoring of existing signals but also discovering patterns and correlations that remained hidden due to the limitations of our natural physiology.

Innovative technical features

The development of these nanocomposites represents a unique convergence of disciplines that solves traditionally intractable problems in flexible electronics.

- Adaptive conductivity: Maintenance of electrical properties under repetitive mechanical deformation

- Biocompatibility: Compatibility with human tissues for prolonged monitoring applications

- Scalability: Manufacturing capability from unique prototypes to mass production

- Multifunctionality: Integration of sensing, conduction, and structure in a single material

Advances in manufacturing processes

The implementation of 3D printing for these specialized materials introduces specific advantages that transcend the material's own capabilities.

- Exact geometric customization to adapt to individual anatomies without specialized tools

- Integration of multiple functionalities in unique and simplified manufacturing processes

- Reduction of waste through precise deposition only where functional material is needed

- Possibility of incorporating property gradients within a single printed structure

Future research directions

The current success of these nanocomposites lays the foundation for even more ambitious evolutions in the human-technology interface.

- Development of self-healing materials that maintain conductivity after mechanical damage

- Integration of energy harvesting capabilities from body movement and heat

- Creation of distributed sensory systems that map physiological signals in high spatial resolution

- Combination of passive sensing with actuation for advanced haptic feedback systems

While our body remains limited by millions of years of biological evolution, technology proves that sometimes the best way to understand ourselves is by creating extensions that see what we cannot. 📊 Because, let's be honest, what would be more revealing than a sensor that knows our muscles better than our own brain?