3D-Printed Bone Implants Integrate into Clinical Practice

Creating human bone structures with additive manufacturing technology is no longer a distant idea. Now progress is being made to implement these systems in real medical environments, where they can transform how complex injuries are addressed. 🦴

Materials that Dialogue with the Body

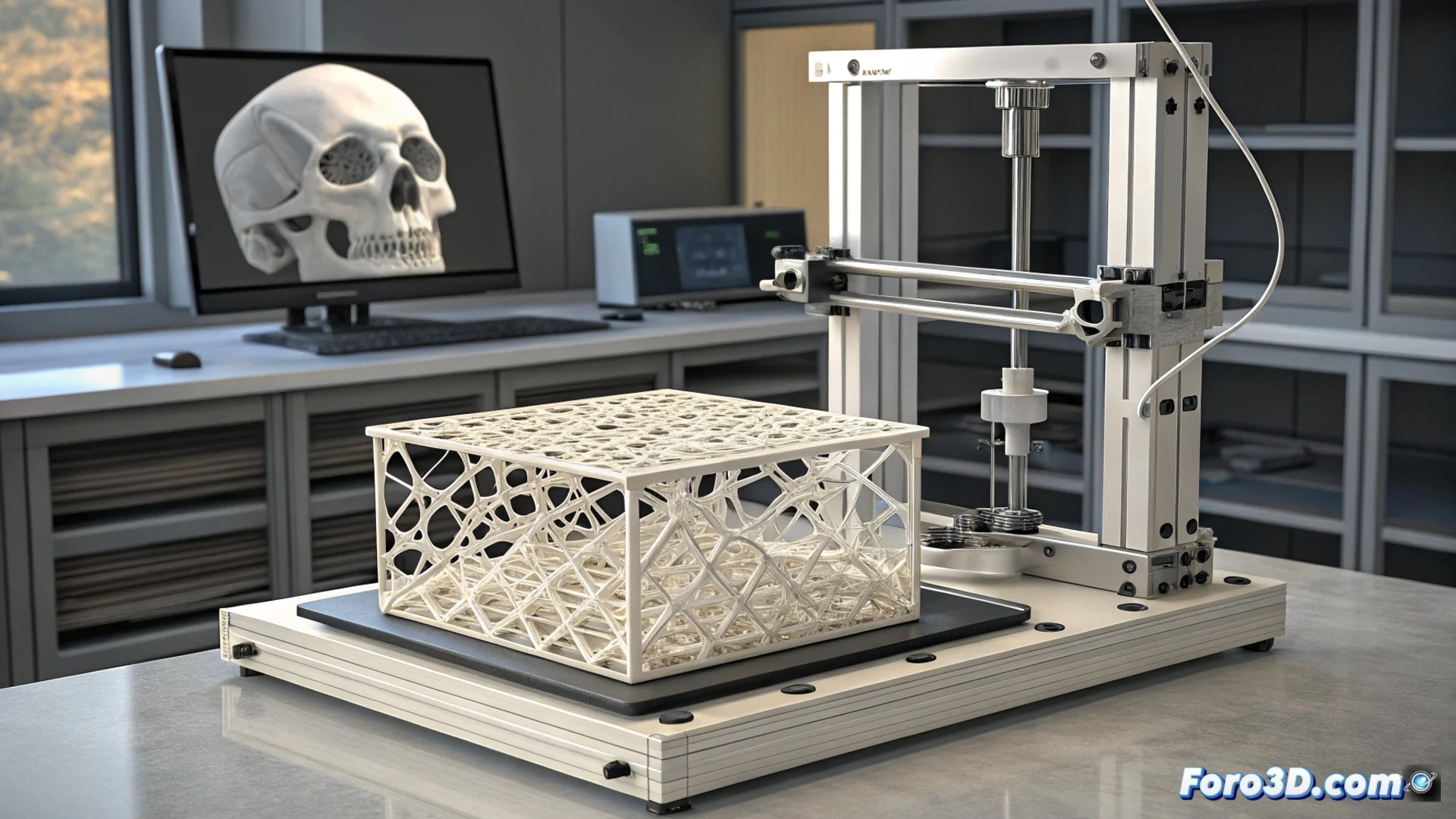

The core of this advancement is bio-inks, compounds that include cells and substances like hydroxyapatite to emulate the natural bone matrix. By depositing layers, porous scaffolds are generated that invite the patient's cells to populate the implant. This support biodegrades in a programmed manner while the body regenerates its tissue, achieving complete fusion.

Key Advantages of Customization:- They are designed from patient scans, ensuring an exact anatomical fit.

- They allow addressing intricate bone damage that conventional methods do not solve well.

- The porous structure facilitates living tissue growth inside the implant.

Repairing a skull or jaw with a custom-made piece no longer belongs to the realm of fiction.

Challenges for Widespread Adoption

Bringing these implants to the operating room requires overcoming technical and regulatory obstacles. Researchers must ensure that the pieces have the necessary strength and are free of contamination. Additionally, printing processes must be fast and consistent to fit into hospital routines. The definitive step is to demonstrate their safety and efficacy through rigorous clinical trials.

Current Areas of Work:- Optimize the mechanical properties of printed materials.

- Ensure absolute sterility of each implant.

- Validate protocols through clinical studies.

A Tangible Future in Orthopedics

Although manufacturing a complete skeleton for transplantation remains a distant horizon, current technology opens immense doors. It is plausible that in the near future, surgeons can request a new bone component with the same operability as they now request an imaging test. The boundary between machine and biology blurs to the benefit of regenerative medicine. 🏥