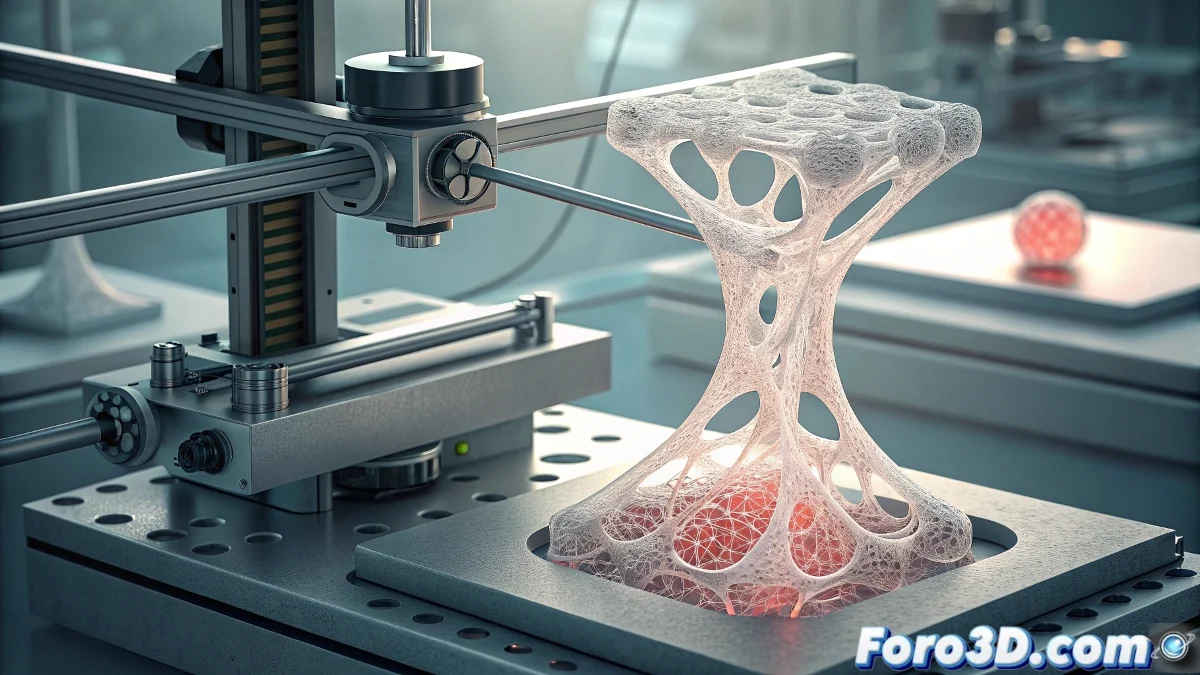

3D-Printable Bioactive Glass: The Revolution in Personalized Bone Regeneration

Regenerative medicine is advancing toward a future where bone implants will no longer be standardized products, but fully personalized solutions. Scientists have developed a 3D-printable bioactive glass specifically designed to replace and regenerate damaged bone. The key innovation lies in a unique formulation of hydrogel composed of silica, calcium, and phosphate that, when cured at low temperatures, forms a bioactive structural scaffold. In preclinical tests with rabbits, this material has demonstrated a superior and sustained capacity to regenerate bone tissue, outperforming traditional materials and opening the door to implants that perfectly adapt to each patient's unique anatomy. 🦴

The Chemical Composition that Mimics Natural Bone

The success of this revolutionary material is based on its strategically designed chemical composition. The silica, calcium, and phosphate hydrogel essentially replicates the main mineral components of natural bone. Silica provides the base structure, while calcium and phosphate—the same ions that form bone hydroxyapatite—stimulate osteogenic cellular activity. The most innovative aspect is the ability of this compound to maintain its structural integrity during the 3D printing process at remarkably low temperatures (below 60°C), which preserves its bioactive properties and avoids thermal damage to surrounding cells when implanted.

Key Components of Bioactive Glass:- Silica (SiO2) as the main structural matrix

- Calcium ions to stimulate bone formation

- Phosphate as a precursor to natural hydroxyapatite

- Hydrophilic polymers to form the hydrogel base

- Crosslinking agents to control degradation rate

The Low-Temperature 3D Printing Process

The ability to 3D print this material at low temperatures represents a significant technological advancement. While many implant materials require high processing temperatures that can compromise their bioactivity, this hydrogel cures through a gentle gelation mechanism. The process involves controlled extrusion of the material through a specialized print head, followed by curing that does not exceed 60°C. This enables the creation of complex structures with controlled porosity that mimic the architecture of spongy bone, facilitating vascularization and cell migration once implanted.

This bioactive glass not only replaces bone but activates the body's natural capacity to regenerate.

Promising Results in Animal Models

In studies with rabbits, the material has demonstrated exceptional performance in bone regeneration. Researchers observed faster and more complete integration with host bone compared to traditional materials like titanium or bioinert ceramics. The bioactive glass acted as a temporary scaffold that gradually degraded as natural bone tissue replaced it, a process known as osteoconductive replacement. Histological analyses showed robust vascularization and mature bone formation within the implant's pores, indicating superior bioactivity that goes beyond simple osseointegration.

Advantages of Customization through 3D Printing

The combination of bioactivity and 3D printing enables an unprecedented level of customization in bone implants. Surgeons can use medical imaging (CT scans) of each patient's specific bone defect to digitally design an implant that fits perfectly. 3D printing can then manufacture this exact design, creating implants that match the patient's anatomy millimeter by millimeter. This is particularly valuable for complex defects resulting from trauma, tumor resection, or congenital malformations, where standardized implants often fail to provide an optimal fit.

Potential Medical Applications:- Reconstruction of complex craniofacial defects

- Repair of fractures with significant bone loss

- Replacement of tumor-resected bone segments

- Spinal fusion with customized implants

- Repair of maxillofacial and dental defects

- Bone regeneration in patients with advanced osteoporosis

The Mechanism of Bioactivity and Regeneration

Bioactive glass works through a dual mechanism of action. First, it provides immediate mechanical support that stabilizes the damaged area. Second, and most importantly, it releases calcium and phosphate ions in a controlled manner that stimulate mesenchymal stem cells to differentiate into osteoblasts (bone-forming cells). Simultaneously, the material's surface develops a carbonated hydroxyapatite layer similar to natural bone, which serves as a template for new bone tissue deposition. This process transforms the implant from a synthetic material into functional living tissue.

The Future of Personalized Regenerative Medicine

This development represents a significant step toward fully personalized regenerative medicine. The next horizon includes incorporating growth factors and the patient's own stem cells into the hydrogel matrix before printing, creating "living" implants that further accelerate regeneration. Researchers are also exploring bio-inks with different compositions to create implants with gradient properties that mimic natural variations in bone density and composition within a single implant.

3D-printable bioactive glass marks a turning point in the treatment of bone defects. By combining the anatomical customization of 3D printing with the superior bioactivity of specially designed materials, this approach promises to transform clinical practice, offering patients solutions that not only replace lost bone but activate and support the body's natural regeneration processes. As this technology advances toward human clinical applications, it could mean the end of standardized bone implants and the beginning of an era where every implant is as unique as the patient who receives it.