3D-Printable Bioactive Glass Revolutionizes Personalized Bone Repair

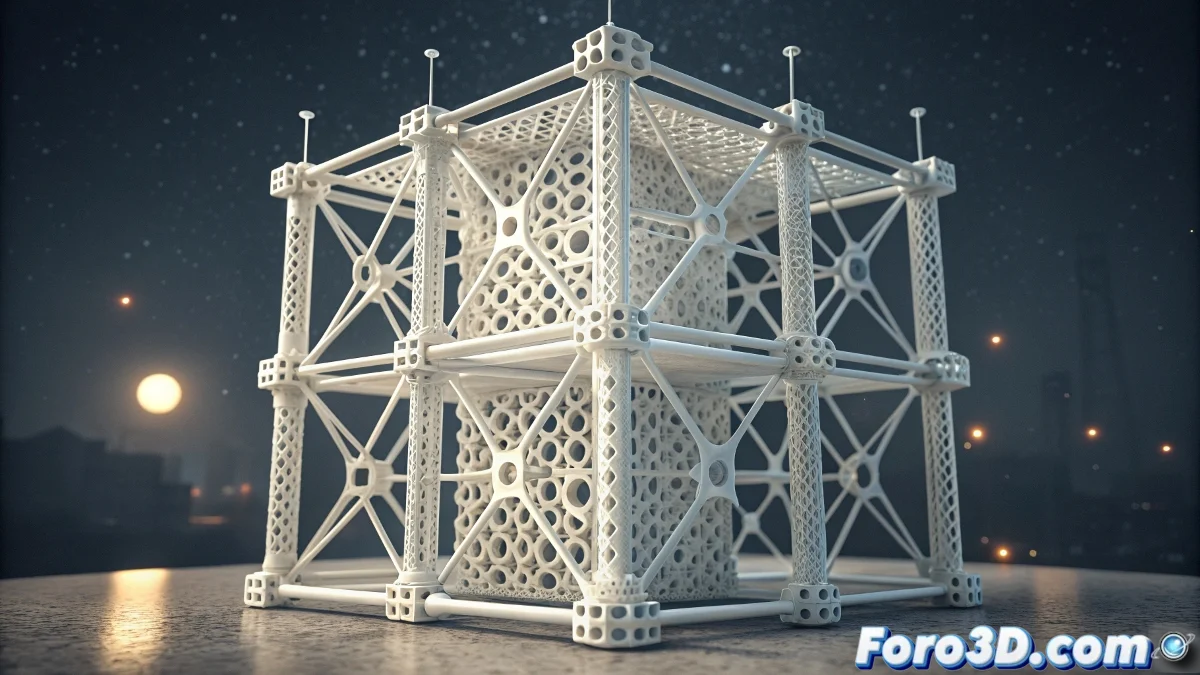

Regenerative medicine reaches new milestones with the development of bioactive materials specifically designed for additive manufacturing. This 3D-printable bioactive glass represents a significant advance in the creation of bone implants that actively interact with human tissue 🦴.

Unique Properties for Accelerated Bone Regeneration

The material combines total biocompatibility with the ability to stimulate the formation of new bone tissue. Its specific chemical composition promotes the generation of hydroxyapatite, the main mineral component of natural bone, facilitating perfect integration.

Key Biomedical Features:- Controlled porosity that allows vascularization and cell migration

- Progressive degradation synchronized with native bone regeneration

- Controlled release of bioactive ions that stimulate osteogenesis

The ability to 3D print bioactive glass with customized geometries marks a before and after in the treatment of complex bone defects

Customization through Additive Manufacturing

Medical 3D printing allows each implant to be adapted to the exact dimensions of the patient's bone defect. This anatomical customization is achieved through computed tomographies that guide the digital design of the structures 🏥.

Surgical Advantages of Customization:- Perfect adaptation to the bone defect morphology

- Reduction of surgical time by eliminating intraoperative carving

- Maximum preservation of remaining healthy bone

Applications in Orthopedics and Reconstructive Surgery

This innovative approach transforms the treatment of complex traumas, congenital defects, and oncological reconstructions. The interdisciplinary combination of materials engineering, digital design, and regenerative medicine opens new frontiers in patient care 💊.