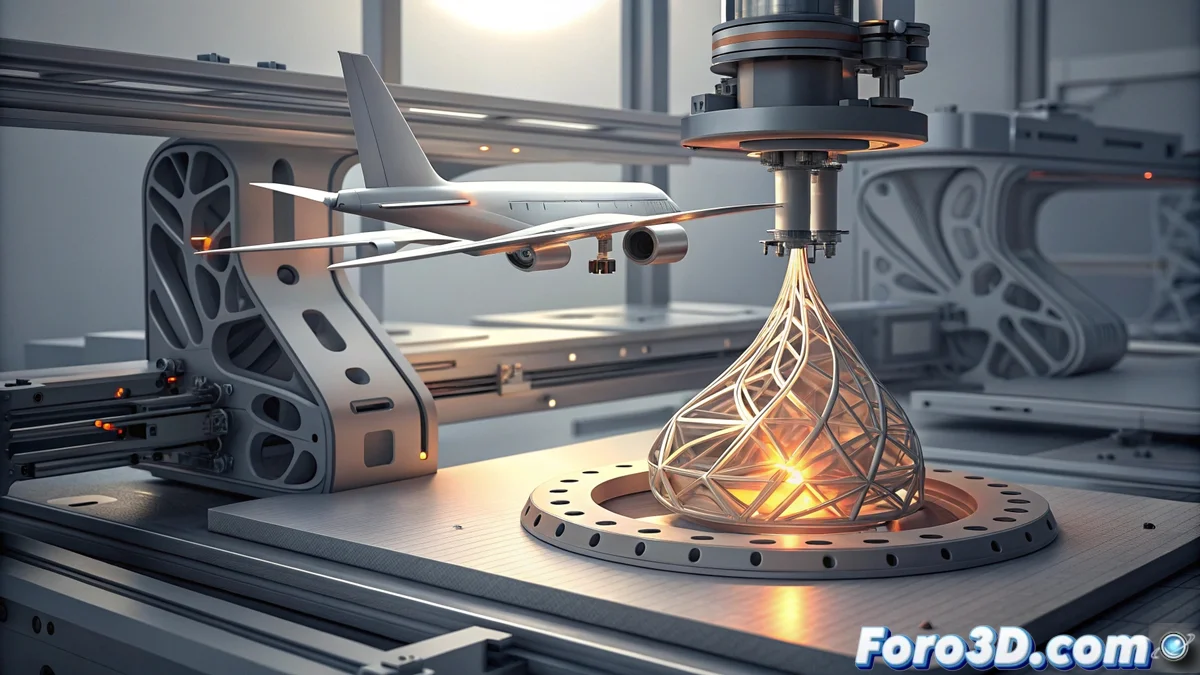

Metal 3D Printing Manufactures Landing Gear Components

The aeronautical industry integrates metal additive manufacturing to create specific parts for landing systems. This approach enables the production of functional prototypes and final components that do not bear the main loads, significantly accelerating design cycles. 🛩️

Key Advantages in Aeronautical Design

The main strength of this technology lies in its ability to materialize optimized geometries. Bionic or topological shapes can be manufactured that distribute mechanical stresses more efficiently, something very costly or directly impossible with traditional machining methods. This potential to lighten parts without compromising their function is vital in aviation, where every gram reduced impacts fuel consumption and overall performance.

Current Applications in the Sector:- Validate designs: Used to test and adjust new component concepts agilely.

- Manufacture non-critical parts: Such as supports, housings, or guides for actuators, where structural requirements are lower.

- Accumulate data for certification: Adoption is gradual, starting with non-structural parts to build confidence and experience.

Companies like Safran Landing Systems are already using this technology to manufacture small supports or housings, paving the way for deeper integration.

The Path to Structural Components

Currently, the role of metal 3D printing in this field focuses on non-structural areas. Commercial aviation has extremely rigorous certification protocols, requiring a prudent and evidence-based implementation. Reliability must first be demonstrated in lower-risk applications.

Limitations and Future Outlook:- Does not yet replace traditional methods: A complete landing gear is not manufactured entirely with a 3D printer.

- Focuses on "smart parts": Complex internal components that previously required multiple milling and assembly processes.

- Reduces dependence on complex workshops: Speeds up the production of specific and customized parts.

Conclusion: An Evolving Technology

Metal 3D printing is consolidating as a valuable tool for developing and producing non-critical components in landing gear. Its ability to create complex geometries that save weight and to accelerate prototyping makes it indispensable. Although its use today is selective, the data collected paves the way for future applications in vital structural elements, slowly transforming how aircraft are manufactured. ✈️