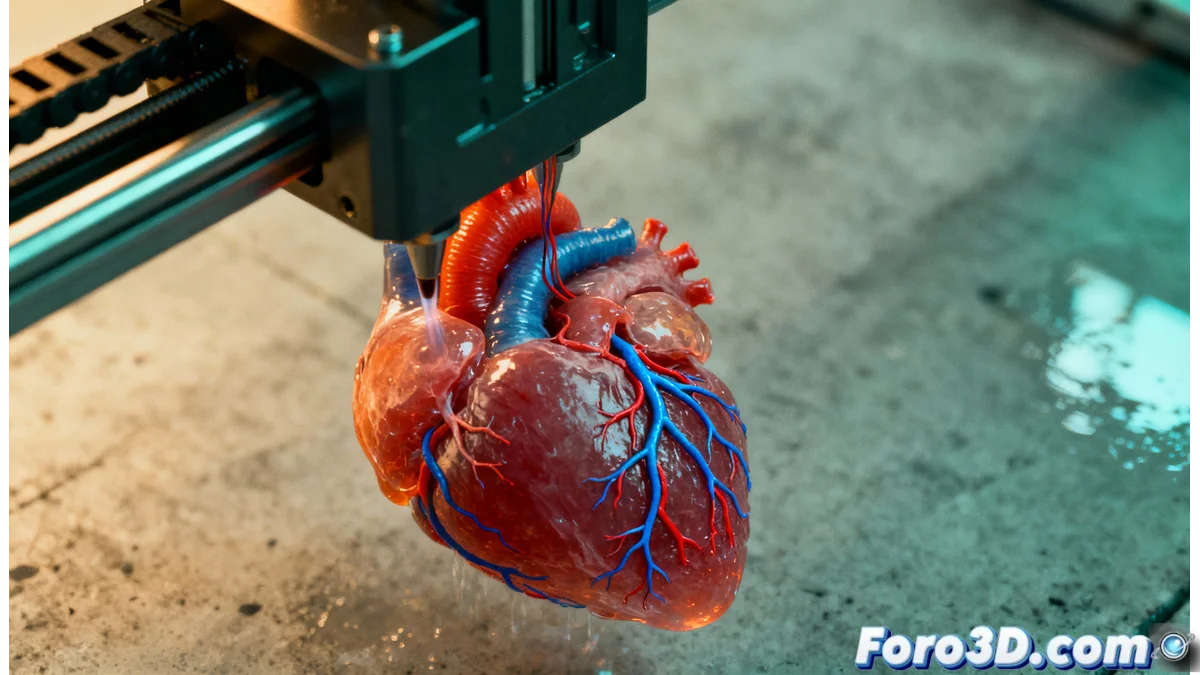

3D Bioprinting and Vascularization in Regenerative Medicine

The three-dimensional bioprinting is radically transforming the field of regenerative medicine by facilitating the manufacture of complex biological structures that incorporate fully operational vascular systems. Scientists use specialized bioprinting devices that deposit successive layers of biocompatible hydrogels enriched with live cells, progressively building tissues with extraordinary submillimeter precision. This technological innovation is overcoming the most significant obstacle in tissue engineering: the creation of functional vascular networks 🩺

Innovative Strategies in Vascular Manufacturing

Contemporary methods implement diverse approaches to generate permeable microvessels that allow blood flow. The injection printing technique uses specialized bioink formulations containing endothelial cells, which have the intrinsic ability to self-assemble into three-dimensional tubular structures. Parallelly, the vascular sacrifice approach involves the fabrication of temporary scaffolds that are subsequently removed, leaving hollow conduits that cells colonize to form blood vessels. More advanced procedures integrate multiple cell types into pre-designed configurations that mimic the structural complexity of natural vascularization, including the functional interconnection between arterioles, capillaries, and venules.

Main Vascular Biofabrication Techniques:- Injection printing with endothelial bioinks that spontaneously self-assemble

- Vascular sacrifice method that creates hollow channels using soluble temporary structures

- Multicellular combination in pre-designed architectures that replicate natural vascular systems

Vascularization represents the holy grail of tissue bioengineering - without it, any printed biological structure lacks long-term viability

Medical Applications and Technical Challenges

These advances have immediate implications for the development of organs for transplantation, pathological models for pharmacological research, and toxicological evaluation platforms. Vascularized tissues enable more accurate analysis of how experimental drugs interact in physiologically representative microenvironments. However, significant challenges persist, such as efficient integration with the patient's circulatory system, post-implant tissue maturation, and scalability to manufacture complete human-sized organs. Regulatory standardization and standardization of these protocols also constitute an active area of development.

Main Clinical Applications:- Development of bioprinted organs for transplant programs

- Creation of disease models for pharmaceutical research

- Toxicity testing platforms with vascularized tissues

Future Perspectives and Ethical Considerations

Vascularized 3D bioprinting continues to evolve toward the creation of increasingly complex functional biological structures. The irony lies in that while we perfect the manufacture of artificial organs, numerous patients remain on transplant waiting lists as if in an endless queue, though with considerably graver prognoses to obtain what they need. The future of this technology promises to revolutionize not only the treatment of diseases, but also our fundamental understanding of human biology and the limits of regenerative medicine 💊